Coalbed methane is released externally due to coal mining activities. Given its low concentration, which renders utilization challenging, China annually vents approximately 285 billion cubic meters of coalbed methane into the atmosphere, leading to significant energy waste and greenhouse gas emissions. To enhance the utilization rate of coalbed methane, mitigate these emissions, and promote a “green and low-carbon” energy supply, this article investigates pressure swing adsorption technology for purifying coalbed methane and analyzes the advantages, disadvantages, and application scopes of three processes: separation based on equilibrium effects, kinetic effects, and steric hindrance effects. The research findings reveal that equilibrium effect-based adsorption is particularly advantageous for purifying low-concentration coalbed methane, effectively capturing methane (CH4). Conversely, when dealing with medium- to high-concentration coalbed methane, methods leveraging kinetic effects prove more favorable. Within the context of equilibrium effects, activated carbon serves as a suitable adsorbent; however, achieving high-purity products entails substantial energy consumption. The methane saturation adsorption capacity of novel activated carbons has reached 2.57 mol/kg. Kinetic effect-based adsorbents, primarily carbon molecular sieves and zeolite molecular sieves, are characterized by lower energy demands. Currently, coal-based molecular sieves have achieved a CH4/N2 equilibrium separation factor of 4.21, and the amount of raw coal required to produce one ton of carbon molecular sieve has decreased to 2.63 tons. In light of the rapid advancement of intensive coal mining operations and the swift implementation of smart mine construction, there is an urgent need to intensify research on large-scale purification technologies for low-concentration coalbed methane. This will provide the technical foundation necessary for achieving “near-zero emission” of mine gas and facilitate the achievement of the goals of carbon peak and carbon neutrality.

(1) PSA technology can increase the concentration of methane in coalbed methane, reduce the emission of greenhouse gases, and minimize energy wastage, thereby offering a solution for carbon emission reduction in the coal industry. Current PSA separation processes are often solely based on equilibrium effects or kinetic effects. For coalbed methane with low methane content, the equilibrium effect-based adsorption of CH4 presents a significant advantage. In cases of medium- to high-concentration coalbed methane, where the nitrogen content to be removed is relatively small, a kinetic effect-based N2-selective adsorption process is more advantageous. If, in the future, the goal is to purify low-concentration coalbed methane to above 90% purity, it should involve a combination of separation processes based on both equilibrium and kinetic effects.

(2) In the equilibrium effect scenario, activated carbon is commonly utilized as an adsorbent. Methane, being a strongly adsorbing component, is preferentially adsorbed.The product gas must be obtained from the bottom of the tower through vacuum withdrawal. To achieve a high-concentration product, the number of stages must be increased, leading to higher overall energy consumption. Currently, the methane saturation adsorption capacity of newly developed activated carbons has reached 2.57 mol/kg, and there has been a significant reduction in the regeneration energy consumption of the adsorption tower and the amount of activated carbon used. Modifying activated carbon to enhance the equilibrium separation coefficient of the adsorbent is a direction for future research.

(3) Adsorbents operating on kinetic effect principles primarily consist of carbon molecular sieves and zeolite molecular sieves, which feature lower energy consumption and are suitable for medium- to high-concentration coalbed methane with higher methane content. Due to the high cost of carbon molecular sieves and zeolite molecular sieves, developing efficient and cost-effective selective adsorbents represents a future research direction. Currently, significant advancements have been made in the technology of producing molecular sieves from coal, with the CH4/N2 equilibrium separation factor reaching 4.21, and the amount of raw coal required to produce 1 ton of carbon molecular sieve has been reduced to 2.63 tons.

(4) With the rapid advancement of intensive and high-intensity mining in coal mines and the rapid implementation of intelligent mining construction, research on large-scale purification technology for low-concentration coalbed methane should be strengthened, especially in the study of mixed adsorption materials and highly selective adsorbents , increasing the adsorption capacity of molecular sieves, reducing costs, providing technical and equipment support for “zero emission” coal mine gas,and helping to achieve the goals of “carbon peak and carbon neutrality”.

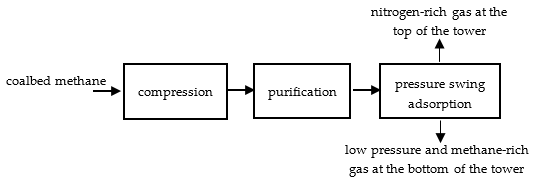

Figure 1. Process flow chart of methane enrichment by counterbalance effect

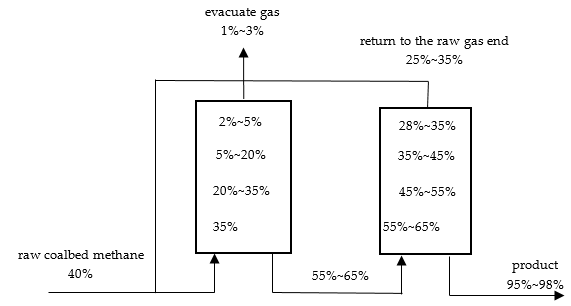

Figure 2. Schematic diagram of a two-stage PSA process based on equilibrium effect

Figure 3. Four-tower coalbed methane separation device using PSA